Request a quote

Vendor Name

Description

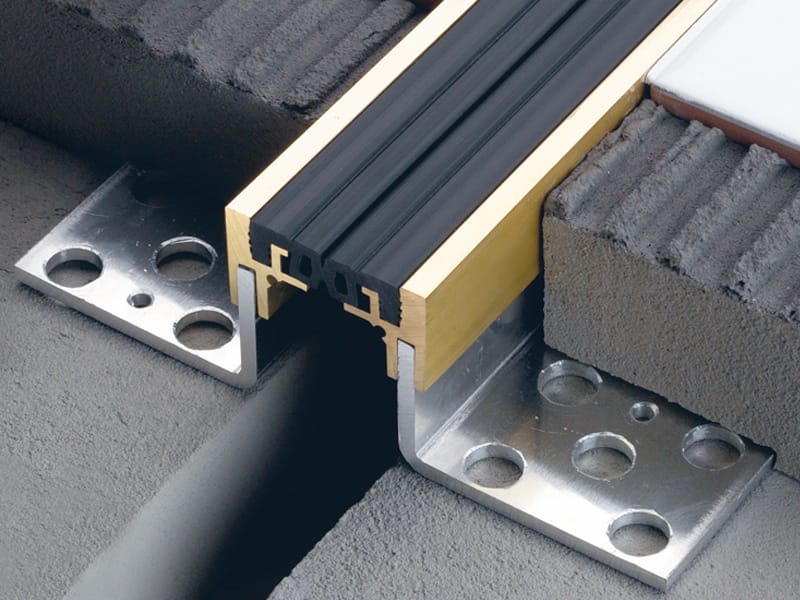

JOINTEC GM - GML By PROFILITEC

Collection: Jointec

Type: Modular structural joint

JOINTEC GM - GML - Modular structural joint adjustable to different heights with visible upper part in either brass or aluminium and lower module in aluminium. Designed to bear structural movements of large sized buildings. They are installed over the spaces existing between two semi-detached parts of a building of smaller entity or between different beam bays. They can connect and close these inter-spaces adjusting themselves up-wards, downwards and even transversally, according to the shrinkage-settlement movements of the building, either cyclic or permanent. Within the flooring bays frame created with the structural joints, a further surface subdivision with a suitable pattern of movement joints should be always provided for. Settlements of the structure, expansion and compression due to thermal excursion, shrinkage and structural bending are elements that create continuous movements and stresses in the flooring that often generate problems of cracking or premature detachment of the covering. It is therefore a good idea to provide an adequate grid of expansion joints during installation, choosing the type of joint and its location in consideration of the loads and stresses to which the cladding will be subjected and the different thermo-hygrometric linear expansion coefficients of the bedding and tiles and the possible interactions between different materials. The splitting of the surface and the screed underneath is in fact decisive in order to guarantee a workmanlike laying in both the adhesive and traditional methods. Always foresee a joint - In correspondence with a change in the substrate material and/or the casting joints. - In correspondence with pre-existing discontinuities in the substrate, such as structural expansion joints and different screed blocks. - At fixed elements such as columns and doors. - At changes in the laying direction. - At points where the tiled surface meets walls or containing elements. The resulting modules should be as regular as possible. As a general rule, the proportion between the two sides should not exceed 2:1.