Request a quote

Vendor Name

Description

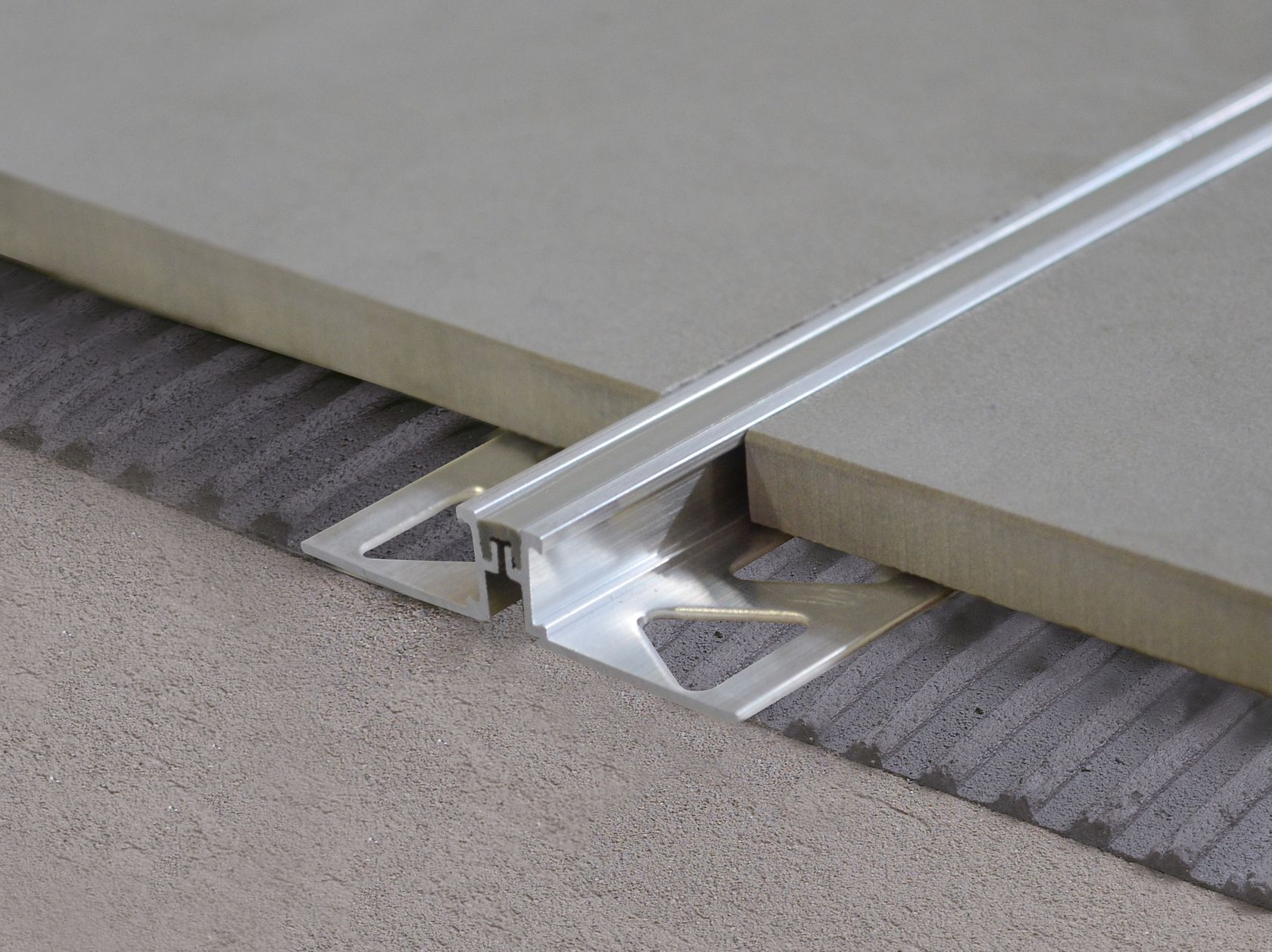

COFLEX CBR By PROFILITEC

Collection: Coflex

Product code: CBR

Type: Aluminium Flooring joint

COFLEX CBR is composed of a twin double metal profile to host the internal rubber seal. This product has been designed to ensure a certain grade of protection to the tile and relative work load it may have to bear. The synthetic rubber insert efficiently compensates and absorbs flooring movements along with the covering material. COFLEX CBR is suitable to bear distributed weights and tensions. Select a joint with the height matching exactly the tile thickness, the joint must not rise above the level of covering surface but should be laid 0,5 ÷ 1 mm below the edge of the tiles. Suggested flooring bays 10-25 m² (as per standard UNI 11499:2013). Typical flooring areas: retail shops, hotels, sporting centers and schools. Settlements of the structure, expansion and compression due to thermal excursion, shrinkage and structural bending are elements that create continuous movements and stresses in the flooring, which often generate problems of cracking or premature detachment of the covering. It is therefore advisable to provide an adequate grid of expansion joints during installation, choosing the type of joint and its location in consideration of the loads and stresses to which the coverings will be subjected, and the different coefficients of linear thermal expansion of the bedding and tiles and the possible interactions between different materials. The splitting of the surface and the screed underneath is in fact decisive in order to guarantee a workmanlike laying in both adhesive and traditional methods. Always provide for a joint: - In correspondence with a change in the substrate material and/or the joints. - At pre-existing discontinuities in the substrate, such as structural expansion joints and different screed blocks. - At fixed elements such as columns and doors. - At changes in the laying direction. - At points where the tiled surface meets walls or containing elements. The resulting modules should be as even as possible. In general, the proportion between the two sides should not exceed 2:1.